No products in the cart.

Zero TDS Reverse Osmosis Water Filtration System For Autoclave Sterilizers

$999.00 – $1,448.00 Inc. GST

Reverse Osmosis Water Filtration System For Autoclave Sterilizers

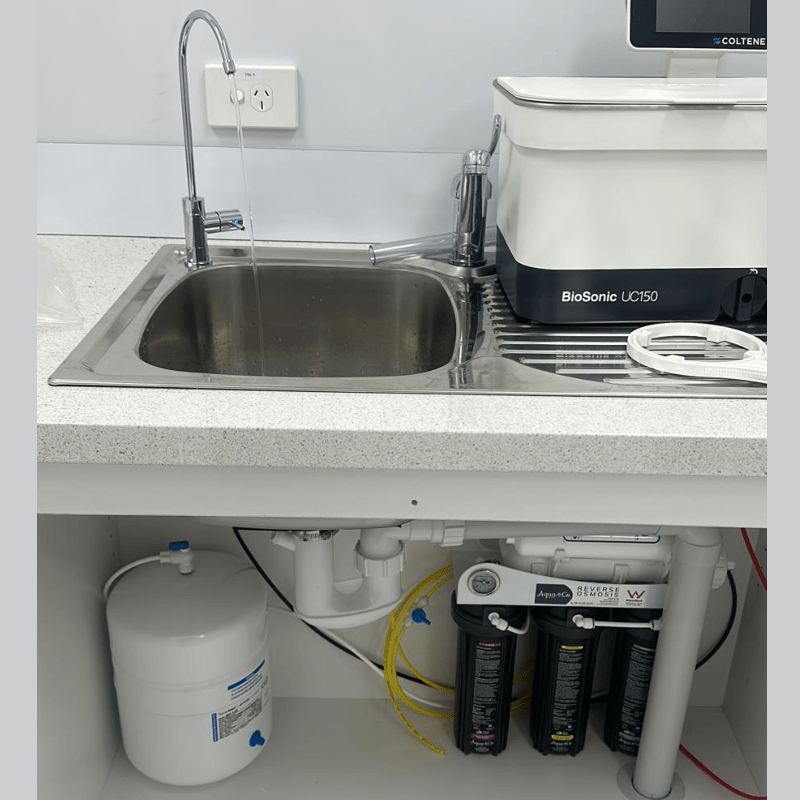

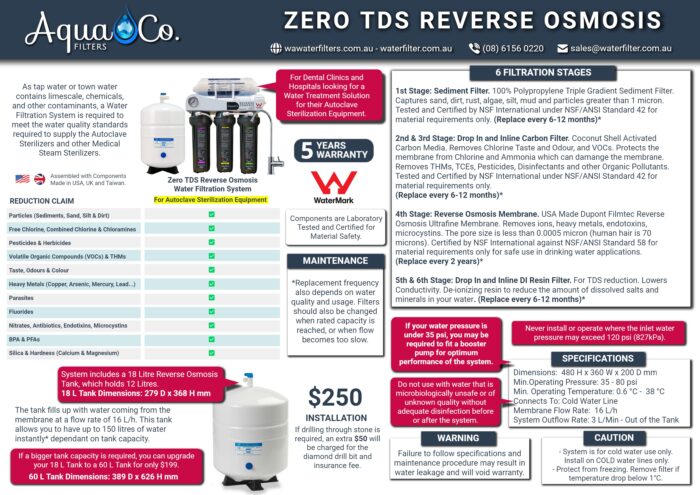

Autoclave Sterilizers and other Medical Steam Sterilizers require a permanent water supply to provide adequate steam during the sterilization process. As tap water or town water contain limescale, chemicals, and other contaminants, a Water Filtration System is required to meet the water quality standards required by manufacturers in instruction manuals.

- For Dental Clinics and Hospitals looking for a Water Treatment Solution for Medical Steam Sterilizers.

- Assembled in Australia by Industry Professionals using components Made in the USA, Taiwan and UK.

- The most effective and advanced water filtration system to deliver the best quality steam for the sterilisation process.

- Components are Laboratory Tested and Certified for material safety.

- No Electricity Required*. This water filtration system is completely mechanical, works with water pressure (>35psi).

⚠️ This system is for use on cold water line only. Hot water may damage the system.

Pair it with:

Brochure Installation Guide

- Description

- Dimensions

- Contaminant Reduction

- Filtration Stages

- Maintenance

- Installation Guide

- FAQs

- Specifications

- Certifications

- Dimensions: 480 H x 360 W x 200 D mm

- Standard – 18 Litre RO Tank (holds 12 Litres): 279 D x 368 H mm

- Upgrade – 60 Litre RO Tank (holds 40 Litres): 389 D x 626 H mm

Zero TDS Reverse Osmosis Water Filtration System For Autoclave Sterilizers. Compared to traditional filtration technologies that rely on a screen or filter to remove particles, reverse osmosis (RO) provides the finest level of filtration. The RO membrane acts as a barrier to all salts and inorganic molecules, as well as organic molecules. It is therefore the most effective process for removing contaminants such as: Endotoxins/pyrogens, Insecticides/pesticides, Herbicides, Antibiotics, Nitrates, Sugars, Soluble salts, and Metal ions. See Contaminant Rejection List

Autoclave Sterilizers require a permanent water supply to provide adequate steam during the sterilization process. As tap water or town water contains limescale, chemicals, and other contaminants, a Water Filtration System is required to meet the water quality standards required by manufacturers in instruction manuals.

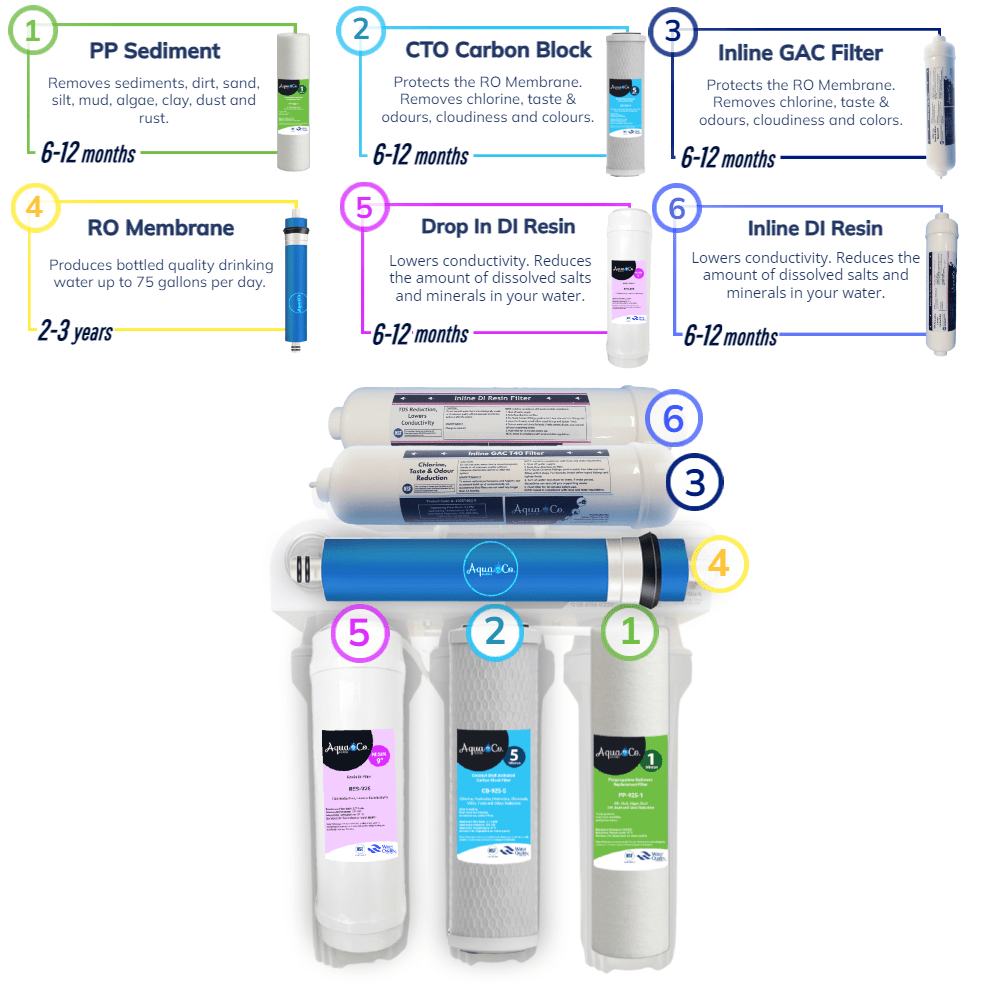

STAGE 1 PARTICLE FILTER

The Zero TDS Reverse Osmosis Water Filtration System has a sediment filter in the first stage which will capture sand, iron particles and suspended matter. This filter has 3 layers. The outer layer has 10 µm, the middle layer has 5 µm and the inner layer has 1 µm. In this way, the dirt is trapped throughout the filter, and not only on the surface like other sediment filters.

STAGE 2 & 3 ACTIVATED CARBON FILTER

The Zero TDS Reverse Osmosis Water Filtration System has a coconut shell activated carbon filter which through adsorption filtration. This filter will adsorb Chlorine and other disinfectants used in the scheme water supply. Also, will protect the main component in the filtration system, the reverse osmosis membrane.

STAGE 4 REVERSE OSMOSIS MEMBRANE – WATER SOFTENER

The Zero TDS Reverse Osmosis Water Filtration System has a reverse osmosis membrane in the third stage. This membrane will capture all the calcium, salts, organic and inorganic molecules. As a result, the water will be softened.

This is the main component as will also will prevent scale from building up in your Autoclave Sterilizer and will protect your equipment from corrosion.

The Zero TDS Reverse Osmosis Water Filtration System will ensure the best quality steam during the sterilization process.

STAGE 5 & 6 ION EXCHANGE FILTERS

The Zero TDS Reverse Osmosis Water Filtration System has two ion exchange filters in the last two stages for TDS reduction. De-ionizing resin filters are used to reduce the amount of dissolved salts and minerals in your water.

These values are taken based on the Tuttnauer Automatic Autoclave Instruction Manual .

- Stage 1: Sediment Pre-Filter – Replace every 6-12 months

- Stage 2 & 3 : Carbon Filter – Replace every 6-12 months

- Stage 4: Ultrafine TFC RO Membrane – Replace every 1-2 years

- Stage 5 & 6: Resin Inline Filter – Replace every 6-12 months

Zero TDS Reverse Osmosis Replacement Filter Cartridges

⚠️ This system is for use on cold water line only. Hot water may damage the system.

Installation GuideWhat are the benefits of the ZERO TDS Reverse Osmosis?

- Produces High Quality Deionised Water. Meets water quality requirements for Autoclave Sterilization Machines and other Medical Steam Sterilizers.

- The reverse osmosis membrane is the only effective filtration media to remove meet the water quality for steam sterilisers.

- Efficiently rejects all contaminants that are of concern to the consumers – such as Chloramines, Chlorine, Pesticides, Fluorides, and Heavy metals.

- Particles larger than the membrane pore size (.0005 micron) are rejected and washed down the drain.

- Reverse osmosis effectively reduce the TDS levels in water. Other systems (not reverse osmosis), reduce chemicals, but not reduce the TDS levels.

⚠️ This system is for use on cold water line only. Hot water will damage the system.

- Model: AquaCo Zero TDS Reverse Osmosis

- Part Number: SYS-RO925TM5

- Filtration Method: Mechanical, Adsorption, and Reverse Osmosis

- Filter Size: 9″ x 2.5″

- Filtration Stages: 6

- Brand: AquaCo

- System Dimensions: 480 H x 360 W x 200 D mm

- Standard – 18 Litre RO Tank (holds 12 Litres): 279 D x 368 H mm

- Upgrade – 60 Litre RO Tank (holds 40 Litres): 389 D x 626 H mm

- Max. Operating Pressure: 80 psi

- Never install or operate where inlet water pressure may exceed 120 psi (827kPa)

- Min. Operating Pressure: 35 psi

- If your home pressure is under 35 psi, you may be required to fit a booster pump for optimum performance of the system.

- Connects To: Cold Water Line

- For Cold water use only. Install on COLD water lines only.

- Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

- Min. Operating Temperature: 0.6 °C

- Protect from freezing. Remove filter if temperature drops below 1°C.

- Max. Operating Temperature: 38 °C

- Hot water will damage the system.

- Membrane Flow Rate: 16 L/h

- System Outflow Rate: 3 L/Min Out of the Tank

Contents:

- 3 x Housing Sumps

- 3 x Housing Caps

- 1 x Reverse Osmosis Tank

- 1 x Bracket

- 1 x Spanner

- 1 x Polyspun Sediment Filter

- 2 x Carbon Block Filter

- 1 x Reverse Osmosis Membrane

- 2 x DI Inline Filter

- Accessories for Installation: Mains Connector, Drain Clamp, Flow Restrictor, Check Valve, Shut Off Valve, Pressure Limiting Valve.

System components are made in manufacturing facilities certified by ISO 9001 and ISO 14001. All high pressure housings/casings are constructed out of chemical resistant reinforced polypropylene and is pressure tested beyond industry standards.

- Reverse Osmosis Tank, Certified to ANSI/NSF 58

- Reverse Osmosis Membrane, Certified by NSF International against NSF/ANSI Standard 58 for material requirements only for safe use in drinking water applications.

- Dedicated Chrome Chrome Tap, Certified to NSF/ANSI 61 Section 9-G. This faucet is Tested and Certified by NSF International against NSF/ANSI 42, 58 for materials and structural requirements.

- Sediment Filter, Tested and Certified by NSF International under NSF/ANSI Standard 42 for material requirements only.

- Carbon Filter, Tested and Certified by NSF International under NSF/ANSI Standard 42 for material requirements only.

System WaterMark Certification No. 23448

- Other Components – Certifications

System WaterMark Certification No. 23448

Filters and Components are Tested and Certified by NSF International under NSF/ANSI Standard 42 for material requirements only.

Manufacturing facilities are ISO 9001 and ISO 14001 Certified.

ISO 9001 is the ultimate benchmark for quality management, this means products meet expectations and quality standards.

The ISO 14001 refers to the fulfilment in environmental performance requirements such as, resource efficiency, waste reduction, costs easing, environmental impact measurement and competitive advantage in supply chain design, these among others.

- Other Components – Certifications

Our systems are installed by experienced and licensed plumbers.

Related products

Reverse Osmosis Systems

Compact Reverse Osmosis High Alkaline Water Filtration System – Works With Whole House Water Filters

$695.00 – $842.00 Inc. GST

Including Installation

Sale!

Benchtop Filters

$1,895.00 – $2,695.00 Inc. GST

Without-With Installation

$130.00 Inc. GST

RO Membranes

$95.00 – $149.00 Inc. GST

Reverse Osmosis Systems

USA Reverse Osmosis High Alkaline Water Filtration System (RO)

$1,099.00 – $1,246.00 Inc. GST

Without-With Installation

Commercial

$295.00 – $350.00 Inc. GST

Reverse Osmosis Systems

AquaCo Reverse Osmosis High Alkaline Water Filtration System (RO)

$899.00 – $1,046.00 Inc. GST

Without-With Installation